Machine tools

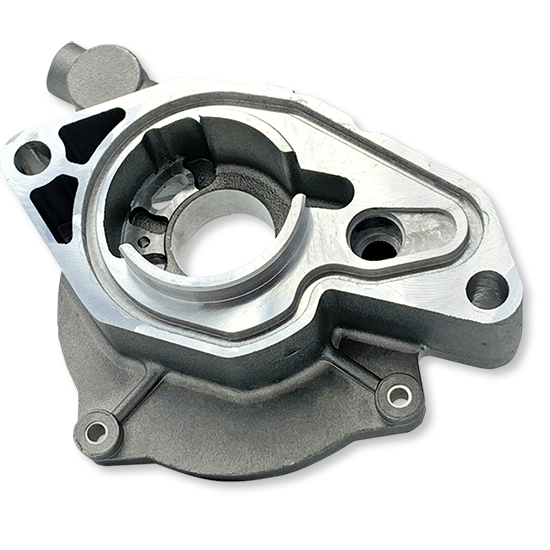

Complete machining of differential gear housings on one machine

• incl. internal machining

• 2 clamping situations

• Cycle time: 94.2 seconds

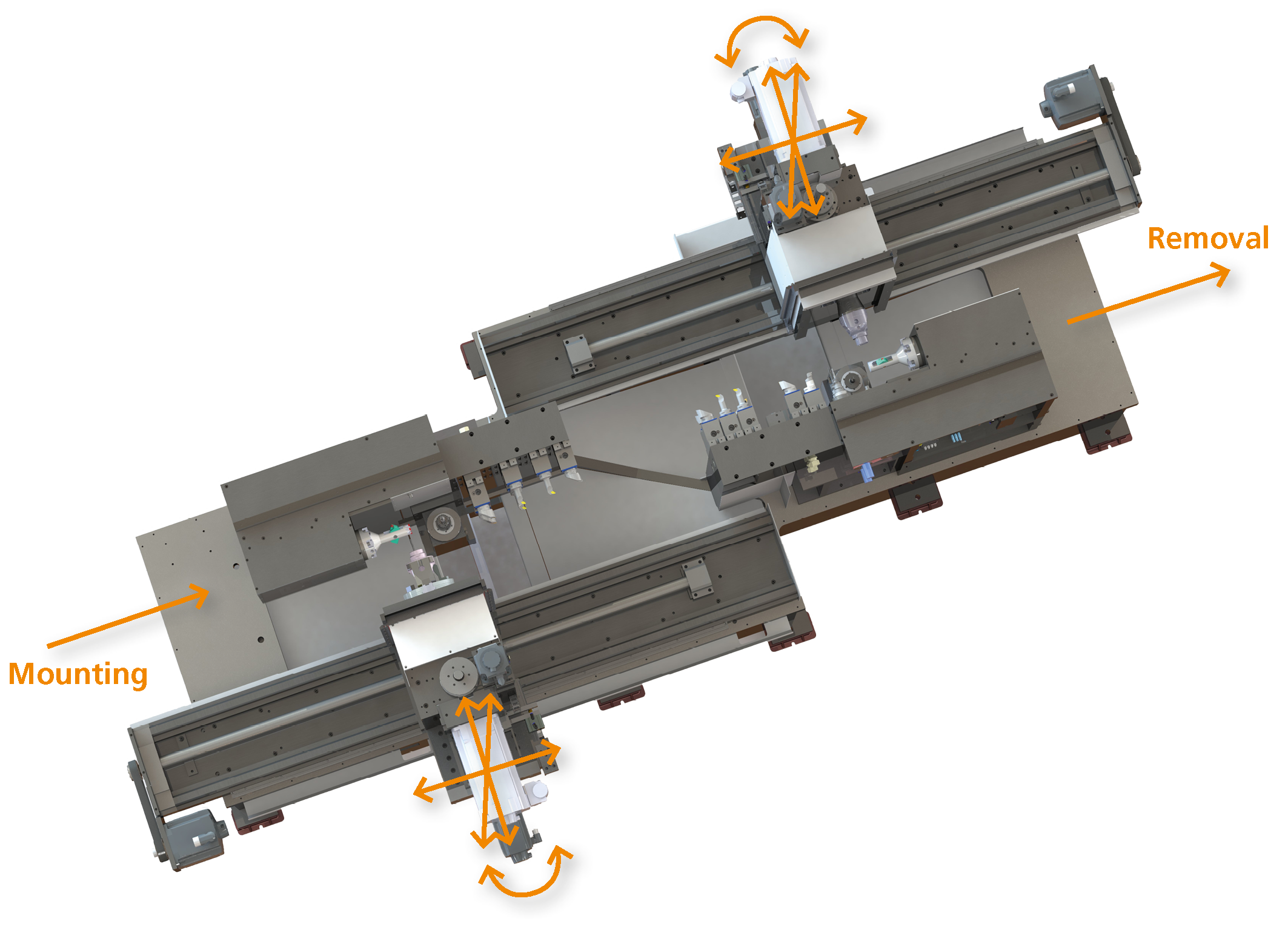

The housings are machined simultaneously by two separately operating main spindles on 6 driven and up to 12 stationary tools.

The machine concept:

Complete and complex machining on only one machine bed

Application – suitable for …

Equipping the plant

The loading conveyor equipped with pallets with a capacity of 20 blanks conveys the workpieces to the machine loading station.

Grippers transfer the workpieces to the clamping device of the first of 2 machining stations.

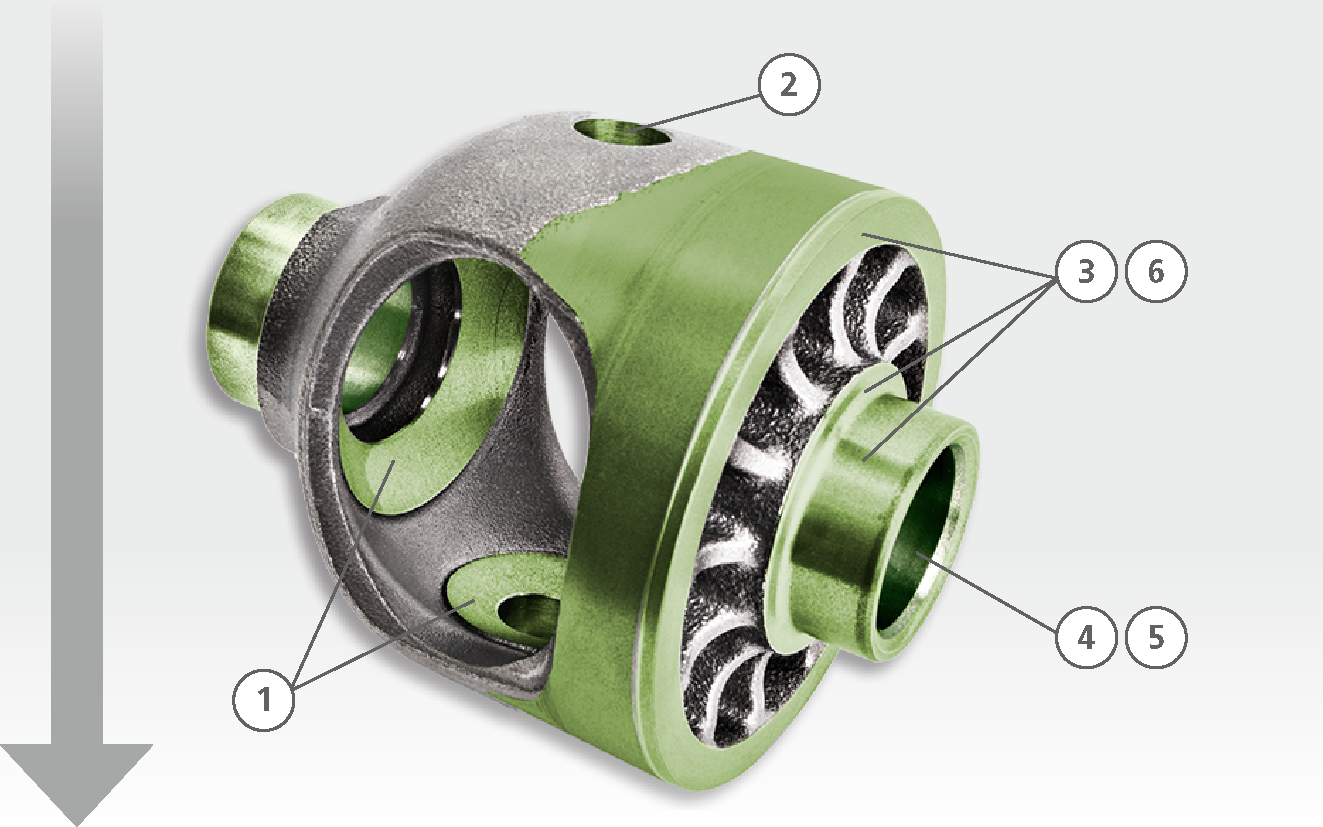

Processing station OP10

grün eingefärbt = bearbeitete Flächen

colored green = processed areas

Work steps

1 Calottes: roughing

2 Bolt hole: pre-drill and deburr, inside and outside

3 Outside diameter and flat surfaces: roughing

4 Inner diameter: roughing

5 Inner diameter: sizing

6 Outer diameter and flat surface: finish

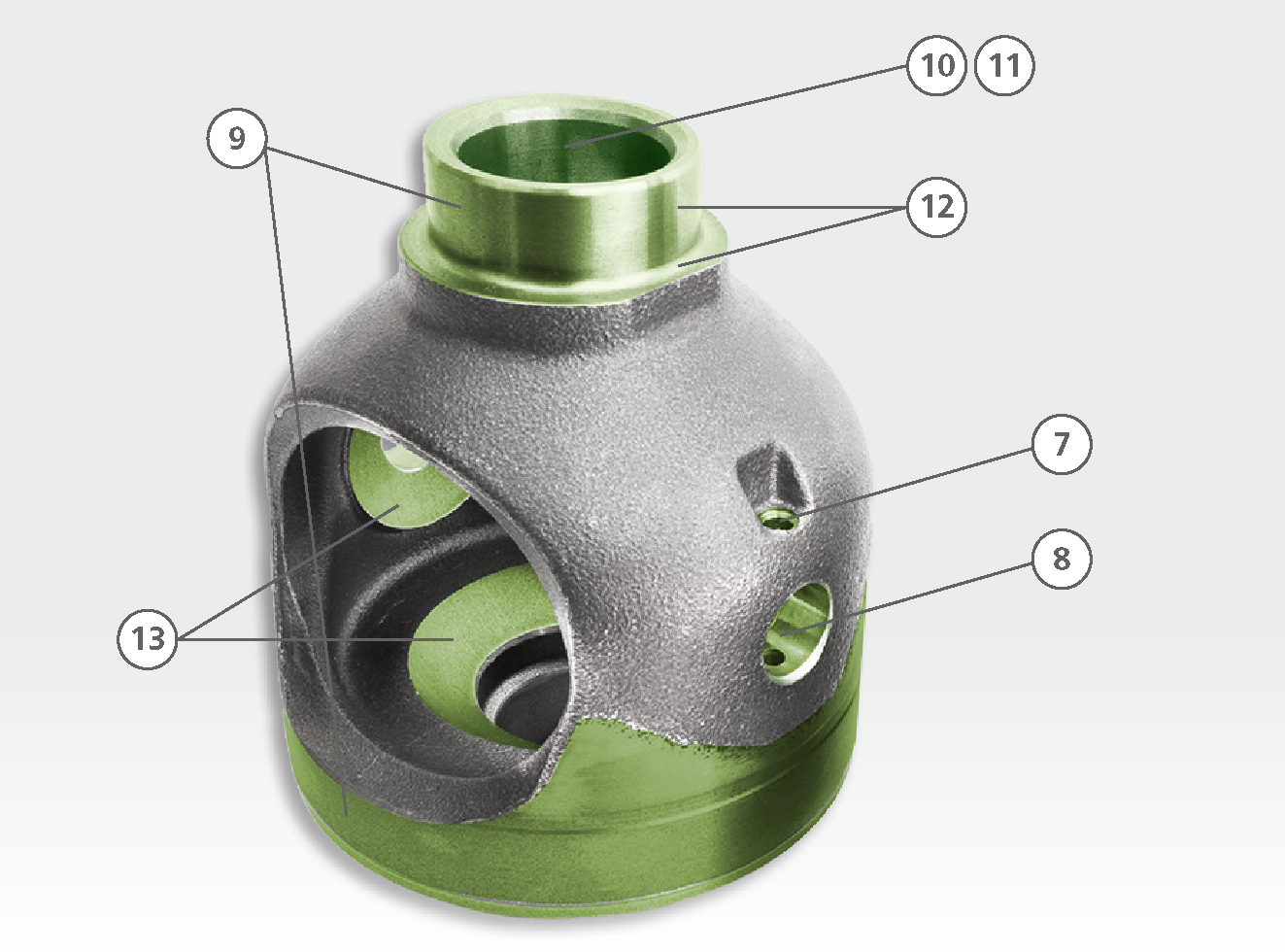

Processing station OP20

7 Pin bore: centering and reaming

8 Bolt hole: reaming

9 Outside diameter and flat surfaces: roughing

10 Inner diameter: roughing

11 Inner diameter: sizing

12 Outer diameter and flat surfaces: finish

13 Calottes: sizing

Highlights

Differential gear housings place the highest demands on a machine tool:

- Rotary machining of a wide range of internal and external surfaces with high accuracies

- Precise insertion of holes

- Machining of spherical inner surfaces, fits and contours

- Optimum use of the actuating tool: the workpiece is moved to the actuating tools via the main spindles, which can be moved in X, Y and Z, with the tools plunging horizontally radially into the differential gear housing

- The entire machining process, including internal machining of the differential housings, is carried out by just one machine with only 2 clamping situations

100% control and removal

All finished differential gear housings are fed to a measuring machine via a drain station after machining. The results of the 100 % measurement are used by the control system for automatic tool correction.

If the measurement results meet the specifications, the workpieces are removed via an accumulation conveyor in combination with a robot arm.

Equipment |

|

| 2 driven actuating tools | 50 Nm / 20,3 kW / 4500 min-1 |

| 2 driven vertical radial drilling units | 16 Nm / 8,9 kW / 6000 min-1 |

| 2 driven axial drilling units | 3 Nm / 0,82 kW / 3000 min-1 |

2 main spindles |

|

| Torque | 125 Nm |

| Power | 34,2 kW |

| Rotations | 3000 min-1 |

Peripherie |

|

| Loading conveyor with individual pallets for position-oriented insertion into the machine | |

| Blow-off unit | |

| Measuring station for 100% measurement | |

| Unloading cell with industrial robot | |

| Unloading dust belt for finished parts | |

Machine dimension |

|

| Machine tool | 4850 mm x 2870 mm |

| Machine tool incl. periphery | 8000 mm x 4000 mm |