SF Spindle

for high-speed milling, grinding, drilling, engraving

Manual tool change

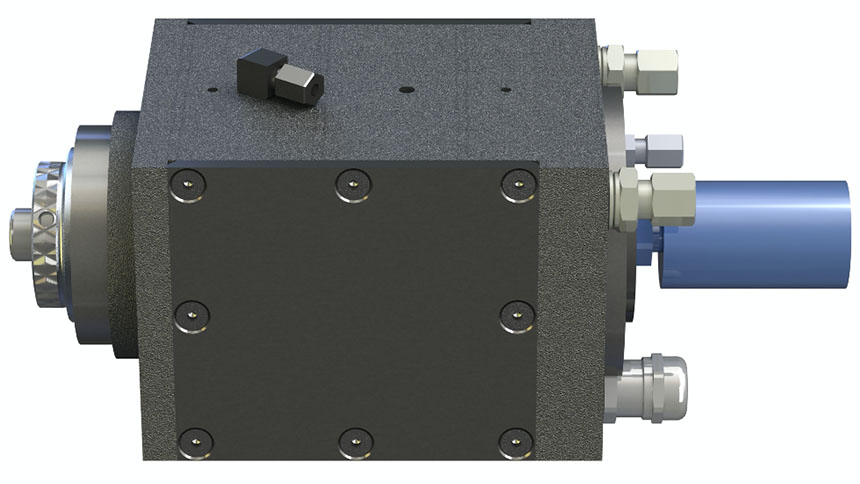

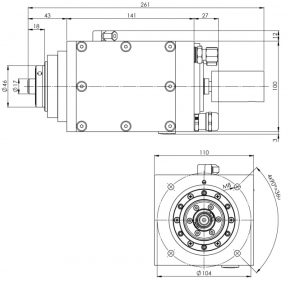

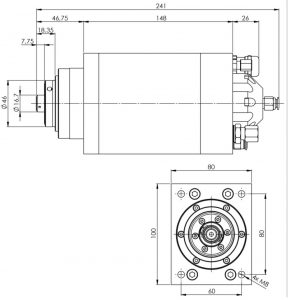

SF Spindle MO-008-001-00

Stock

Spindle bearing: 2 pieces

Oil-air mixture lubrication: maintenance-free

Engine

Motor technology: 3-phase asynchronous drive (brushless and sensorless)

Frequency: 295 Hz

Number of motor poles: 1 pair

Rated speed: 17.700 min-1

Power ratings (liquid cooled)

S1-100 %

Power: 1,50 kW

Voltage: 360 V

Current: 3,7 A

Torque: 0,77 Nm

The specified data apply to sinusoidal voltages and currents. For frequency inverter operation, the effective fundamental wave voltage must correspond to the specified motor voltage. In addition, measured currents may be higher than the specified values due to the harmonic content.

Features

Motor protection: 1 x PTC 130 °C

Housing: stainless steel/aluminium

Housing cross section: 110 x 100 mm²

Mounting: Variable bracket

Cooling: Liquid-cooled

Ambient operating temperature: + 10 °C … + 45 °C

Sealing air: Yes

Protection class (sealing air switched on): IP54

Tool change: Manual tool change

interface: HSK-C 32

Direction of movement: Right

Device connector: 6-pin (M23x1 with vibration protection) or free conductor end

Connection cable: cable with PUR jacket (suitable for drag chains and wet rooms)

Length of connection cable: 3 m (standard, other lengths possible)

Weight: ~ 11,7 kg

Concentricity inner cone: < 1 µ

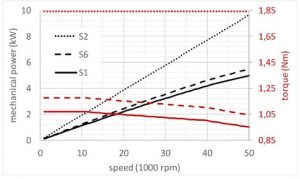

Performance diagram

(liquid cooled)

The performance was determined on a standardized engine test bench.

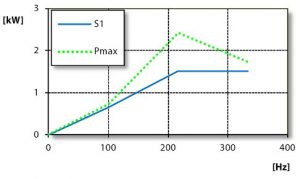

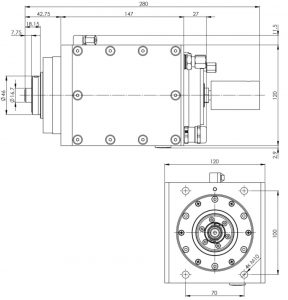

SF Spindle MO-010-001-00

Stock

Spindle bearing: 2 pieces

Oil-air mixture lubrication: maintenance-free

Engine

Motor technology: 3-phase asynchronous drive (brushless and sensorless)

Frequency: 517 Hz

Number of motor poles: 2 pairs

Rated speed: 15.000 min-1

Power ratings (liquid cooled)

S1-100 %

Power: 2,50 kW

Voltage: 380 V

Current: 6,9 A

Torque: 1,62 Nm

The specified data apply to sinusoidal voltages and currents. For frequency inverter operation, the effective fundamental wave voltage must correspond to the specified motor voltage. In addition, measured currents may be higher than the specified values due to the harmonic content.

Features

Motor protection: 1 x PTC 130 °C

Housing: stainless steel/aluminium

Housing cross section: 120 x 120 mm²

Mounting: Variable bracket

Cooling: Liquid-cooled

Ambient operating temperature: + 10 °C … + 45 °C

Sealing air: Yes

Protection class (sealing air switched on): IP54

Tool change: Manual tool change

interface: HSK-C 32

Direction of movement: Right

Device connector: 6-pin (M23x1 with vibration protection) or free conductor end

Connection cable: cable with PUR jacket (suitable for drag chains and wet rooms)

Length of connection cable: 3 m (standard, other lengths possible)

Weight: ~ 15,9 kg

Concentricity inner cone: < 1 µ

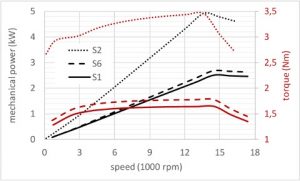

Performance diagram

(liquid cooled)

The performance was determined on a standardized engine test bench.

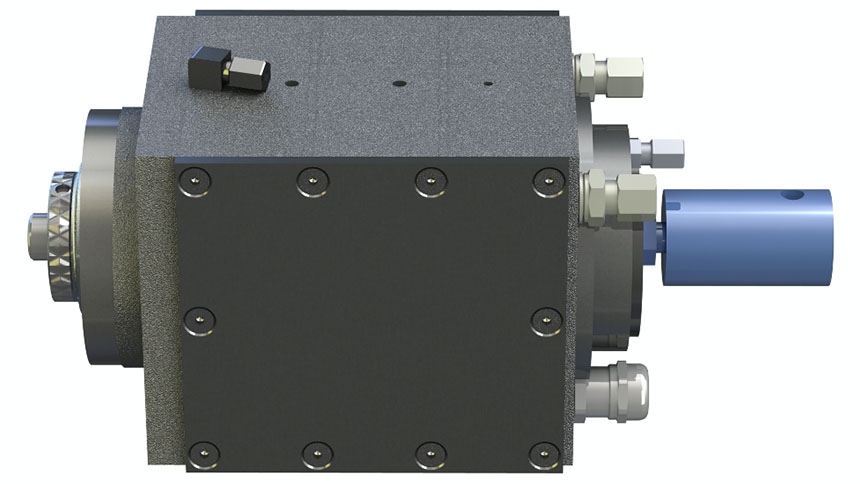

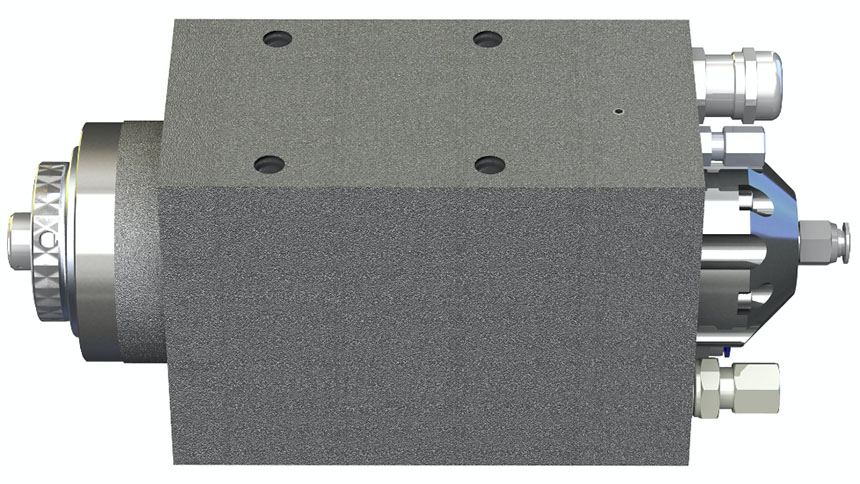

SF Spindle MO-013-001-00

Stock

Spindle bearing: 2 pieces

Oil-air mixture lubrication: maintenance-free

Engine

Motor technology: 3-phase asynchronous drive (brushless and sensorless)

Frequency: 667 Hz

Number of motor poles: 2 pairs

Rated speed: 20.000 min-1

Power ratings (liquid cooled)

S1-100 %

Power: 2,10 kW

Voltage: 130 V

Current: 11 A

Torque: 1,05 Nm

The specified data apply to sinusoidal voltages and currents. For frequency inverter operation, the effective fundamental wave voltage must correspond to the specified motor voltage. In addition, measured currents may be higher than the specified values due to the harmonic content.

Features

Motor protection: 1 x PTC 130 °C

Housing: stainless steel/aluminium

Housing cross section: 100 x 80 mm²

Mounting: Variable bracket

Cooling: Liquid-cooled

Ambient operating temperature: + 10 °C … + 45 °C

Sealing air: Yes

Protection class (sealing air switched on): IP54

Tool change: Manual tool change

interface: HSK-C 32

Direction of movement: Right

Device connector: 6-pin (M23x1 with vibration protection) or free conductor end

Connection cable: cable with PUR jacket (suitable for drag chains and wet rooms)

Length of connection cable: 3 m (standard, other lengths possible)

Weight: ~ 8,9 kg

Concentricity inner cone: < 1 µ

Performance diagram

(liquid cooled)

The performance was determined on a standardized engine test bench.