HK-CON GmbH Mechanical Engineering

Production plants | Assemblies | Engineering services

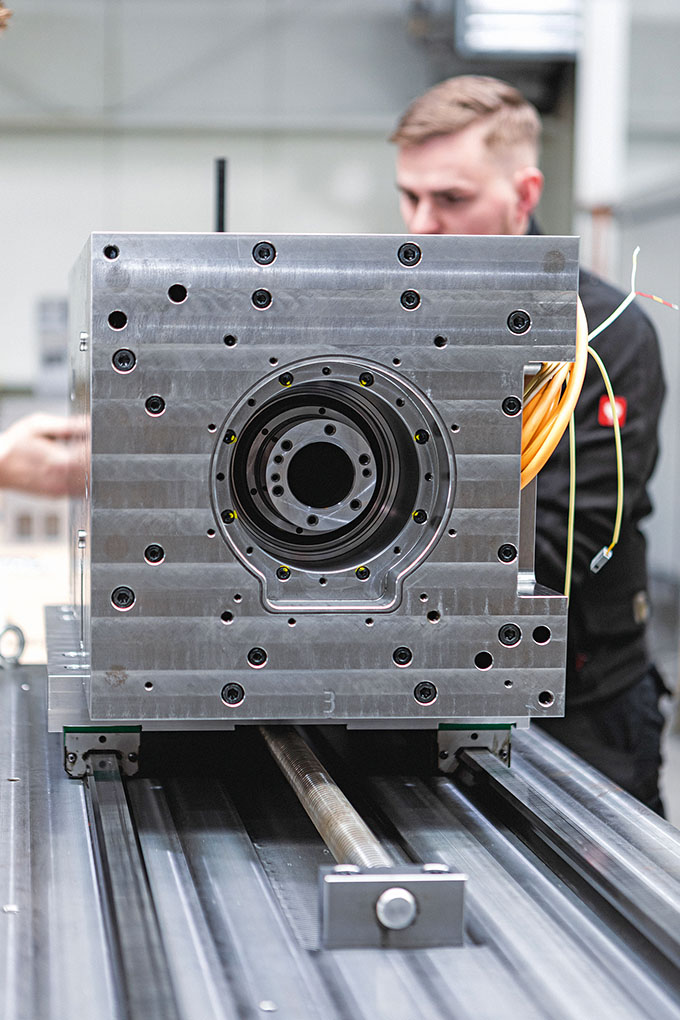

HK-CON GmbH Maschinenbau from Fulda develops, designs and manufactures automated, multi-axis CNC turning and milling centres for individual large-scale production. The basis is formed by modular production units that are flexibly and economically combined with the respective optimum technologies for the most diverse applications.

Single-, two-spindle and multi-spindle solutions can be realised with the HK-CON modular system as well as applications with driven tools for drilling, milling, turning and grinding. In addition, tool turrets and tool magazines with quick-change devices are also in use. All HK-CON machines are designed for highly productive, automated operation.

The company employs around 60 people.

Our products and services:

- Machining systems, machines

- Production cells

- Automation systems (transporting, gripping, sorting, detecting, positioning)

- Application programming (Siemens -S7, CNC Siemens 840 DL, measuring systems, tool breakage monitoring systems, industrial robots Kuka, …)

- Electrical planning (industrial applications, controls, actuators, sensors, bus systems, controllers)

- Switch cabinet construction

- CAD constructions (SolidWorks)

- Manufacturing, contract manufacturing, individual and small series, turning, milling, grinding, welding …

- Device and component assembly, special components, individual components

- Service on machine tools

- Training, product support

»The confrontation of proven solutions with new ideas is the benchmark of our actions«

Our products and services stand for increased effectiveness, competitiveness and sustainability.

Problem analysis, discussion of alternative courses of action, product development, manufacturing, delivery time, training and service support form the basis for our lived customer orientation. Distinct knowledge and many years of experience are in every product.

Good and successful solutions need motivated and competent employees. It is the individual people who make the company what it is. With commitment, creativity and the constant willingness to positively accept the new, efficient plants and systems are created for our partners.

Our offer for you is individually tailored to your specific needs. No matter what task you have for us or in which industry you are active.

Let us tackle tasks and solutions together.

Greetings from Fulda

Walter Kraft

Reinhold Kraft

Waldemar Hildebrandt

HK-CON The company at a glance

The foundation was based on our knowledge and experience in the mechanical and control design of machine tools for the machining of metals. With our solutions concerning the geometrical position of the working spindles and the tools, the highly efficient production of mass turned and mass milled parts is possible. From the very beginning, we have relied on proven suppliers such as Siemens, Schaeffler, Bosch Rexroth, Festo etc.

By adding automated loading and unloading systems to the machines, further fields of competence were occupied.

Today, plants are no longer conceivable without the use of driverless transport systems, conveyor belts, gantry loaders, industrial robots with various gripper systems, image processing systems and measuring systems. In addition, we have developed our own motor spindles for tools and work spindles, spindles, clamping systems, shaft feed-throughs, tool storage and tool transfer systems.

Our ambition is to always develop user-friendly systems, taking into account the latest technology and costs.

Origin

Regionality makes us strong

We produce exclusively in Fulda. Since 2002, we have been facing all challenges together and growing with them.

HK-CON Expertise

Products, services and solutions

- CAD design of workpieces, assemblies and systems

- Production of automation systems

- Application programming

- Electrical planning, switch cabinet construction

- Manufacture of turning and machining centres for large-scale production

- Parts production, equipment and component assembly

- Service on machine tools, production, process and automation equipment

- Training, production support

Corporate philosophy

We are mechanical engineers with heart and soul. For over 20 years, the name HK-CON has stood for reliably good performance. We fulfil our corporate responsibility towards the environment and society out of conviction. In particular, the protection of our environment is important to us – it is a lived principle in the company. We see intelligent networking, artificial intelligence, Internet-of-Things, new materials and innovative machining processes as an opportunity and incentive to continuously optimise our products.

We actively engage in the qualification of our employees through training and further education. We achieve our result in a cooperation with customers, business partners and in our team that is characterised by honesty and fairness.

The indispensable basis for this is open and transparent communication, which we promote and demand.

Our expertise

Design and engineering services

Whether switch cabinet construction, electrical engineering, mechanics, industrial assembly, automation technology or software development – our qualified personnel will realize your project reliably and on schedule.

A team of specialists, consisting of mechanical technicians and engineers, process engineers and production planners (work preparation) will take on tasks in the fields of mechanical engineering, fixtures, test benches, pipeline planning, drive systems or equipment design – from planning and design to construction and commissioning.

Our team services:

- Concept

- Creation of requirement and functional specifications

- Planning and project engineering

- Construction

- Creation of CE documentation according to MRL 2006/42/EG

Automation technology / Software development

The HK-CON team of competent and qualified technicians and engineers realizes your project in automation technology/software development. We complete partial tasks or deliver your project completely from one source – according to your requirements.

We realize planning, project engineering, realization of complete or complex automation solutions including control cabinet construction, electrical design, software development, e-assembly and installation up to commissioning.

- Project planning

- Electrical planning

- Electrical construction

- Electrical assembly and installation

- Software engineering (TIA-Portal, SIMATIC, Rockwell/Allen Bradley, Beckhoff, Wago, Phoenix

- Industrial networks/bus systems

- Process visualization (InTouch, RSView, NI-Lab-View)

- Risk Analyses

- Documentation

- Evaluation of switchgear and control systems

- Retofit of old systems

- Control cabinet construction

- Commissioning

- Safety evaluation

- Siemens Solution Partner Automation

- Siemens FA Safety Integrated Specialist

- System Integrator (Allen Bradley)

- Wonderware System Integrator (InTouch)

- Siemens SIVACON Technology Partner for LV power distribution systems

Switchgear and control cabinet construction

We at HK-CON plan, design, manufacture, document and assemble your switchgear and control cabinets according to national and international standards as well as manufacturing and testing standards.

- Component assembly

- Component assembly

- Control cabinets and power cabinets

- Type-tested energy distributors

Depending on the task at hand, we implement turnkey automation technology – including 3D visualization, software development, electrical design and process control technology.

Our employees with many years of experience are permanently trained and know their trade. Thus we guarantee highest quality and on-time deliveries – made in Fulda – from the center of Germany.

Before commissioning, we test our systems thoroughly in our own test facility. Functional tests and simulations round off HK-CON’s range of services at the highest level.